Future Trends in Cable Management and Earthing Systems

Future Trends in Cable Management and Earthing Systems Introduction As electrical systems become increasingly complex, effective cable management and earthing systems are more critical than ever. With advances in technology and growing emphasis on sustainability and safety, the future of these systems is evolving rapidly. In this blog, we’ll explore the latest trends shaping the future of cable management and earthing, highlighting innovations that promise improved performance, safety, and eco-friendliness. Smart Cable Management Solutions Integration of IoT and Sensors The future of cable management includes smart systems equipped with IoT sensors that monitor cable health, temperature, and load in real time. This enables predictive maintenance, reducing downtime and preventing failures. Modular and Scalable Designs Flexible and modular cable trays and conduits allow for easy expansion and reconfiguration, supporting evolving infrastructure needs without extensive downtime or cost. Enhanced Materials and Coatings Advanced materials resistant to corrosion, heat, and UV exposure extend the lifespan of cable management systems, especially in harsh environments. Innovations in Earthing Systems Use of Conductive Polymers and Nanomaterials Emerging materials like conductive polymers and nanomaterials offer improved conductivity and corrosion resistance, making earthing systems more durable and efficient. Grounding Systems for Renewable Energy Tailored earthing solutions are being developed for solar farms, wind turbines, and other renewable installations, addressing unique challenges such as soil resistivity and lightning protection. Smart Earthing Monitoring Similar to cable management, smart sensors can continuously monitor earth resistance and detect faults, enabling proactive maintenance and enhanced safety. Sustainability and Environmental Considerations Eco-Friendly Materials The use of recyclable and low-impact materials in cable trays and grounding electrodes aligns with global sustainability goals. Energy-Efficient Installations Optimized designs that minimize energy losses and support renewable energy integration are becoming standard. Regulatory Compliance and Standards Future systems will increasingly adhere to stricter environmental and safety regulations, driving innovation in design and installation practices. Challenges to Overcome High initial costs for smart technologies Need for skilled workforce to install and maintain advanced systems Integration with legacy infrastructure in existing facilities Conclusion The future of cable management and earthing systems is exciting, driven by technology, sustainability, and safety demands. Embracing these trends will lead to smarter, safer, and greener electrical infrastructures that meet the needs of tomorrow’s world.

Earthing for Renewable Energy Projects: Why It’s Crucial

Earthing for Renewable Energy Projects: Why It’s Crucial Introduction In the rapidly growing renewable energy sector, ensuring the safety and reliability of systems is paramount. One of the often overlooked yet vital components of renewable energy projects like solar farms and wind turbines is earthing—also known as grounding. Proper earthing for renewable energy projects is essential to protect equipment, ensure safety, and comply with regulations. In this blog, we will dive into why earthing is crucial, how it works, and best practices to implement it effectively. What Is Earthing Earthing means connecting electrical systems and equipment to the ground to safely dissipate excess electrical current. It helps prevent electric shocks, damage to equipment, and electrical fires caused by faults such as lightning strikes or insulation failures. Why Is Earthing Crucial for Renewable Energy Projects? Safety of Personnel Renewable energy installations often operate in outdoor environments where electrical faults can pose serious risks. Proper earthing protects workers and users from electric shocks by safely redirecting fault currents into the earth. Equipment Protection Surges from lightning and electrical faults can damage expensive components like inverters, transformers, and control units. Earthing systems protect this equipment by providing a safe path for high voltage currents. System Performance and Reliability A well-designed earthing system reduces electromagnetic interference and electrical noise, enhancing the performance of sensitive equipment such as sensors and communication devices. Regulatory Compliance Most countries mandate specific earthing standards for electrical installations. Following standards such as IEC 60364 and IEEE 80 ensures compliance, avoiding penalties and operational delays. Efficient Fault Detection Earthing helps in quickly detecting and isolating faults, facilitating faster maintenance and reducing downtime. Types of Earthing System Earthing: Connecting the neutral point of transformers or generators to earth. Equipment Earthing: Grounding metallic parts of electrical equipment that do not carry current. Lightning Protection Earthing: Specialized grounding systems to safely dissipate lightning strikes. Best Practices for Earthing Renewable Energy Projects Conduct Soil Resistivity Tests: Understand the soil’s conductivity to design effective grounding systems. Use Corrosion-Resistant Materials: Copper and galvanized steel ensure longevity. Maintain Low Ground Resistance: Aim for resistance below 1 ohm to ensure safety and performance. Regular Inspection and Maintenance: Earthing systems should be tested periodically. Integrate with Lightning Protection: Especially important for wind farms and large solar arrays. Common Challenges High soil resistivity in rocky or dry areas Corrosion due to saline or acidic soil conditions Poor coordination between design and installation teams Inadequate testing and maintenance procedures Conclusion Earthing is a fundamental safety and performance aspect of renewable energy projects. It protects lives, safeguards equipment, improves system efficiency, and ensures compliance with safety regulations. As renewable energy installations become more widespread, prioritizing proper earthing is crucial for long-term success.

Cable Tray Manufacturer in Pune | GI, SS & Ladder Trays – UPROTEC

Cable Tray Manufacturer in Pune: Choose Quality and Reliability Introduction In today’s industrial and commercial infrastructure, cable trays play a vital role in supporting electrical wiring and cables. For businesses and contractors in Pune, finding a reliable and experienced cable tray manufacturer is crucial. UPROTEC stands out as a Cable Tray Manufacturer in Pune, offering superior quality, customized designs, and cost-effective solutions. Why Cable Trays Are Important Cable trays are essential for organizing and protecting electrical cables in industrial, commercial, and residential setups. They ensure: Safe routing of power and communication cables Easy maintenance and future expansion Enhanced cable life by reducing wear and tear When sourced from a reputable cable trays manufacturer in Pune, we provide long-lasting performance even in demanding environments. Galvanized Iron (GI) Cable Trays Galvanized Iron (GI) cable trays are steel trays hot-dipped in zinc, which creates a protective coating that prevents rust. This zinc layer makes GI trays highly corrosion-resistant, able to withstand moisture, chemicals and harsh weather. In practice this means GI trays are strong and durable, providing long life and support for heavy cable loads without sagging. GI cable trays also meet fire-safety requirements, giving them an edge in industrial and commercial installations. Many Pune-based manufacturers offer GI cable trays because they balance cost and performance – they are less expensive than stainless steel yet still very robust. Corrosion Resistance: Zinc-plated steel resists rust, so GI trays endure humid or corrosive environments. High Load Capacity: Solid steel construction means GI trays support heavy power cables without bending or sagging. Fire & Safety Compliance: Hot-dip galvanization provides heat resistance and meets fire-safety standards. Cost-Effectiveness: GI trays are more affordable than stainless steel, offering similar strength for a lower price. Stainless Steel (SS 304) Cable Trays Cable trays made from SS 304 (18% chromium, 8% nickel stainless steel) are prized for their exceptional corrosion and heat resistance. SS 304 trays do not rust or oxidize easily, even when exposed to water, salts or chemicals, so they last much longer in aggressive environments. They also retain strength at high temperatures, making them ideal for industrial settings with heat or fire risk. For example, SS 304 trays are commonly used in chemical plants, power plants, offshore facilities and food-processing sites where hygiene and durability are critical. Although stainless steel trays cost more upfront, their maintenance needs are minimal, ensuring a very long service life. Superior Corrosion Resistance: SS 304’s stainless composition prevents rust in corrosive or outdoor settings. High Temperature & Chemical Resistance: The alloy tolerates heat, acids and alkalis without degrading. Durability & Longevity: Stainless trays stay strong over time, reducing replacement costs. They are ideal for demanding Pune projects (e.g. petrochemical or food facilities) that require hygienic, non-corroding infrastructure. Ladder-Type Cable Trays Ladder-type cable trays consist of two parallel side rails connected by cross “rungs,” forming an open ladder-like structure. This sturdy design provides excellent support for heavy or bundled cables – ladder trays have very high load-bearing capacity and won’t sag under weight. The open rungs allow air to circulate freely, which dissipates heat from the cables and reduces overheating. In Pune’s industrial and large-complex projects, these trays streamline cable routing: they can be easily mounted on walls or ceilings and modified on the fly as needs change. The result is neater, safer cable runs: ladder trays keep cables organized and spaced apart to prevent tangling or abrasion, which simplifies maintenance. Heavy-Duty Support: Robust metal rungs support large power cables and busbars without bending. Excellent Ventilation: Open design lets air flow around cables, improving cooling and system reliability. Flexible Installation: Modular ladder sections can be quickly joined, rerouted, or expanded, cutting installation time and labor. Safe Cable Management: Trays keep cables orderly and separated, minimizing damage and easing troubleshooting. Benefits of Choosing UPROTEC As a trusted cable tray manufacturer , we offer: Customized Designs – Tailored solutions for your unique requirementsCorrosion-Resistant Coating – GI or powder coating for a longer lifespanQuick Turnaround Time – Fast delivery without compromising on qualityCompetitive Pricing – Value-for-money solutions for every scale of project Moreover, our experienced team ensures that every product undergoes strict quality checks before delivery. Applications of Our Cable Trays Our cable trays are widely used across: Solar power plants Commercial buildings Manufacturing industries IT data centers Warehouses and logistics hubs So, whether you’re setting up a new facility or upgrading an existing one, UPROTEC has the right solution for your cable management needs. Why Choose U-Protec as Your Cable Tray Manufacturer in Pune U-Protec is a Pune-based cable tray manufacturer renowned for quality and customization. Established in 2016, the company operates ISO 9001:2015–certified Pune factories and uses premium materials (galvanized steel, aluminum, stainless steel) in all trays. U-Protec offers a one-stop range of cable management products – from perforated and ladder trays to solid troughs, covers, accessories, and raceway systems – serving residential, commercial and industrial projects. The U-Protec team emphasizes quality control and expert engineering, ensuring each tray meets stringent standards for strength and durability. Customers in Pune benefit from U-Protec’s tailored solutions and responsive service: the company provides custom tray designs when needed and prides itself on on-time delivery and cost-effective pricing. Certified Quality: State-of-the-art Pune facilities and ISO-certified processes guarantee reliable, high-durability products. Full-Range Supplier: As a one-stop cable tray source, U-Protec supplies GI trays, SS 304 trays, ladder trays, perforated trays, cable tray covers, accessories, raceways and more. Customized Solutions: Skilled engineers work with clients to deliver project-specific tray layouts and finishes, so complex Pune projects get exactly the right system. Competitive & Timely: U-Protec combines value pricing with fast turnaround. They commit to on-schedule delivery and after-sales support, helping Pune contractors stay on schedule. Conclusion If you’re searching for a dependable cable trays manufacturer in Pune, UPROTEC is your go-to partner. Our focus on quality, innovation, and customer satisfaction has made us a preferred choice in the region. Contact us today to get a quote or schedule a consultation for your project.

How to Choose the Right Earthing Material for Your Project

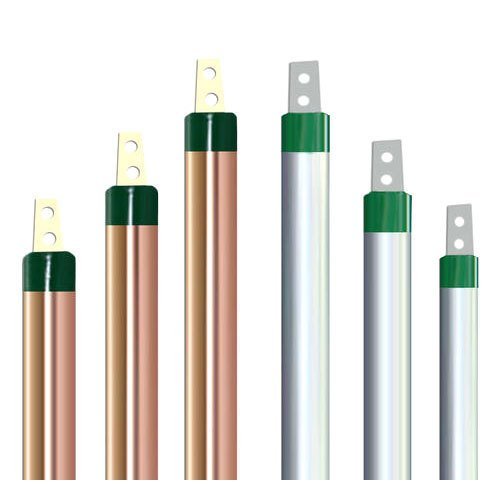

The Right Earthing Material for Your Project When it comes to electrical safety, earthing (or grounding) is a non-negotiable component. Whether you’re working on a commercial, industrial, or residential project, choosing the right earthing material ensures safety, performance, and compliance with electrical standards. In this post, we’ll guide you through how to choose the right earthing material for your project, covering material types, factors to consider, and best practices for optimal performance. Why Earthing Material Matters The main function of earthing is to safely dissipate fault current into the ground. The quality of earthing material directly affects: Electrical safety Equipment protection Voltage stabilization Compliance with local codes (NEC, IEC, IS 3043, etc.) Common Types of Earthing Materials Choosing the right material depends on your application, budget, and environmental conditions. Here are the most commonly used materials: Copper (Bare or Tinned) Advantages: High conductivity Excellent corrosion resistance Long service life Applications: Ideal for critical systems, substations, and high-value installations. Tip: Tinned copper is preferred in areas with high moisture or salinity. Galvanized Iron (GI) Advantages: Cost-effective Widely available Adequate for many commercial applications Limitations: Less corrosion-resistant than copper, especially in aggressive environments. Stainless Steel Advantages: Excellent corrosion resistance Long-lasting in harsh environments Limitations: Lower conductivity than copper, more expensive than GI. Best For: Chemical plants, coastal zones, or high-salinity soils. Aluminum Advantages: Lightweight and relatively affordable Decent conductivity Limitations: Corrodes quickly when buried; not suitable for direct soil contact without coating. Best For: Overhead applications or protected environments. Factors to Consider When Choosing Earthing Material Soil Resistivity High-resistivity soil reduces earthing efficiency. Choose high-conductivity and corrosion-resistant materials like copper for such conditions. Corrosive Environment For acidic or saline soils, opt for stainless steel or tinned copper. GI may corrode rapidly in such environments. Project Type Residential: GI or copper-coated steel rods Industrial/Commercial: Copper or GI strips and plates Critical Infrastructure (Data centers, substations): Pure copper or stainless steel Budget Constraints While copper offers superior performance, it is more expensive. GI is a budget-friendly alternative for low-risk installations. Standards & Regulations Ensure compliance with applicable standards like: IS 3043 (Indian Standard for Earthing) IEC 60364 (International Standards) NEC (National Electrical Code) Best Practices for Earthing System Design Use low-resistance joints and corrosion-resistant connectors Conduct soil resistivity testing before selecting the material Ensure proper earthing electrode size and placement Perform regular testing and maintenance to monitor degradation Conclusion Choosing the right earthing material isn’t just a technical decision—it’s a long-term investment in the safety and performance of your electrical system. From copper’s high conductivity to GI’s affordability, each material has its place depending on environmental conditions, project type, and budget. Still unsure what to use? Consult a certified electrical engineer or conduct a soil resistivity study to make an informed decision. FAQs Q1: Can I mix copper and GI in an earthing system? A: Avoid direct connections between dissimilar metals to prevent galvanic corrosion unless separated by a bimetallic connector. Q2: What is the ideal resistance for an earthing system? A: For commercial/industrial systems, resistance should ideally be <1 ohm. For residential systems, up to 5 ohms may be acceptable. Q3: How often should earthing be tested? A: Test at least once a year, or more frequently in corrosive environments.

How Electrical Safety Regulations Are Changing in 2025

how electrical safety regulations are changing in 2025 Introduction Electrical safety regulations are evolving rapidly to address new technologies, environmental concerns, and increased safety awareness. As we enter 2025, businesses and industries must understand the updated standards to maintain compliance and protect personnel. This blog covers how electrical safety regulations are changing in 2025, highlighting major updates, implications, and best practices. Key Changes in Electrical Safety Regulations for 2025 Stricter Compliance Requirements Regulatory bodies worldwide are tightening compliance criteria, requiring more rigorous documentation, testing, and certification processes for electrical installations. Increased audits and inspections. Enhanced reporting standards for safety incidents. Emphasis on Renewable Energy Systems With the growth of solar, wind, and other renewables, regulations now include specific guidelines for integrating these systems safely into existing grids. New earthing and grounding standards for renewable setups. Updated protocols for inverter and battery safety. Adoption of Smart Safety Technologies Regulations encourage or mandate the use of smart electrical safety devices such as IoT-enabled monitoring systems, automated fault detection, and predictive maintenance tools. Real-time system health monitoring requirements. Data logging and remote diagnostics compliance. Enhanced Worker Safety Protocols Updated standards emphasize worker safety, especially for personnel working in hazardous electrical environments. Mandatory safety training updates. Improved PPE (Personal Protective Equipment) standards. Stricter lockout/tagout procedures. Environmental and Sustainability Considerations New regulations incorporate environmental impacts, promoting the use of eco-friendly materials and processes in electrical infrastructure. Restrictions on hazardous substances in electrical components. Guidelines for energy-efficient system designs. Implications for Businesses and Contractors Increased Investment in Training: Staff need up-to-date knowledge on new safety protocols. Upgrading Electrical Systems: Older installations may require retrofitting or replacement to meet new standards. Enhanced Documentation: Maintaining detailed compliance records becomes critical. Collaboration with Certified Suppliers: Partnering with manufacturers adhering to new regulations is essential. How to Prepare for Regulatory Changes Conduct a comprehensive audit of existing electrical systems. Implement employee training programs focused on new standards. Engage with electrical safety consultants for expert guidance. Invest in modern safety and monitoring technologies. Conclusion The electrical safety landscape is shifting significantly in 2025, driven by technological advances and heightened safety priorities. Staying informed and proactive about regulatory changes is crucial for businesses to ensure compliance and protect workers.

Benefits of Using Maintenance-Free Earthing Systems from U-Protec

Maintenance-Free Earthing Systems from U-Protec Earthing systems are the backbone of electrical safety, protecting both equipment and personnel from electrical faults. Traditional earthing setups often require regular maintenance to ensure their effectiveness, which can be time-consuming and costly. That’s where maintenance-free earthing systems from U-Protec come in — providing a reliable, durable, and hassle-free solution. In this blog, we’ll explore the key benefits of using MFE systems from U-Protec. What Are Maintenance-Free Earthing Systems? MFE systems are specially designed grounding solutions that require little to no upkeep after installation. Unlike conventional earthing systems, they use advanced materials and technology to ensure long-term performance without the need for frequent inspections or repairs. Top Benefits of Using Maintenance-Free Earthing Systems from U-Protec Long-Lasting Durability U-Protec’s MFE systems are made from high-quality materials such as copper-bonded rods and corrosion-resistant alloys. These materials withstand harsh environmental conditions, preventing rust and degradation over time, which means your earthing system stays effective for decades. Reduced Maintenance Costs One of the biggest advantages of a MFE system is the significant reduction in maintenance expenses. Since these systems do not require regular cleaning, testing, or replacement, you save money on labor and material costs. Enhanced Safety and Reliability Reliable earthing is critical for safety. U-Protec’s systems maintain consistent low resistance to earth, minimizing electrical hazards such as shock and fire risks. This dependable performance protects both your infrastructure and personnel around the clock. Easy Installation U-Protec designs its maintenance-free earthing products for quick and easy installation. This reduces downtime during setup and allows for seamless integration with existing electrical systems. Environmental Friendliness With a focus on sustainability, U-Protec ensures that its maintenance-free earthing systems use eco-friendly materials and manufacturing processes. Plus, by eliminating frequent replacements and maintenance, the environmental footprint is further reduced. Compliance with International Standards U-Protec’s earthing systems meet global safety and quality standards such as IEC, IEEE, and IS, ensuring that your installation complies with regulatory requirements. Why Choose U-Protec for Your Earthing Solutions? Proven Expertise: Over years of experience in electrical safety and grounding technology. Innovative Products: Continuous R&D ensures cutting-edge, maintenance-free solutions. Customer Support: Comprehensive support from consultation to after-sales service. Global Reach: Trusted by industries worldwide for reliable earthing products. Conclusion Switching to MFE systems from U-Protec offers unmatched benefits, including cost savings, safety, and durability. Whether for industrial plants, commercial buildings, or infrastructure projects, these systems provide a worry-free grounding solution that stands the test of time. Choose U-Protec for earthing products that guarantee peace of mind with minimal upkeep.

G.I. Strips & Plates Manufacturer in Pune – U Protec Group

G.I. Strips & Plates Manufacturer in Pune Looking for a reliable G.I. Strips & Plates Manufacturer in Pune? At U Protec Group, we specialize in manufacturing high-quality Galvanized Iron (G.I.) Strips and Plates used in a wide range of earthing and electrical grounding systems. What Are G.I. Strips & Plates? G.I. Strips and Plates are vital components in electrical grounding systems. Made from galvanized iron, they offer excellent conductivity and corrosion resistance. These strips and plates are used in homes, commercial buildings, industrial setups, and telecom towers to provide a safe path for fault current to discharge into the ground. Why Choose U Protec Group ? As a trusted G.I. Strips & Plates manufacturer in Pune, U Protec Group is known for: ✅ Superior quality materials ✅ Accurate sizes and custom options ✅ Compliance with IS standards ✅ Timely delivery across Maharashtra and India We serve industries such as electrical, construction, telecom, and infrastructure development. Key Features of Our G.I. Strips & Plates High Conductivity – Ensures efficient grounding Corrosion Resistant – Long-lasting performance Custom Sizes Available – Tailored to your project needs Durable Build – Withstands all weather conditions Applications of G.I. Strips & Plates Our G.I. strips and plates are commonly used in: ✔️ Residential electrical grounding ✔️ Commercial earthing systems ✔️ Industrial equipment protection ✔️ Telecom tower lightning protection Buy Direct from the Manufacturer As a leading G.I. Strips & Plates manufacturer in Pune, U Protec Group offers factory-direct pricing, bulk order support, and customized product solutions. 👉 Contact Us today to request a free quote or discuss your specific requirements. Contact us today to get a free site assessment in Pune. – https://uprotecgroup.com/contact-us/ Read more about our earthing system designs – https://uprotecgroup.com/blog/

Reliable Earthing Solutions in Pune, Maharashtra for Long-Lasting Safety

Reliable Earthing Solutions in Pune Looking for dependable earthing solutions in Pune, Maharashtra? Whether you’re managing a residential project or a large-scale industrial facility, proper earthing is vital to ensure electrical safety, prevent hazards, and comply with statutory regulations. Why Earthing Is Crucial in Pune Pune’s growing infrastructure and rapid urbanization demand robust safety systems. Earthing, also known as grounding, protects electrical installations by directing fault current into the ground. This helps prevent shocks, equipment failure, and fires. That’s why investing in the right earthing solutions in Pune, Maharashtra is essential for both performance and compliance. Types of Earthing Solutions Available Pune-based providers offer a variety of earthing systems to suit different soil conditions, energy loads, and infrastructure types: Chemical Earthing – Low-maintenance and long-lasting, ideal for commercial and industrial setups GI and Copper Electrode Earthing – Offers durability and effective conductivity Plate and Pipe Earthing – Widely used in residential and institutional installations Choosing the right earthing solutions in Pune, Maharashtra depends on your site requirements and the quality of materials used. What to Look for in an Earthing Service Provider A professional earthing provider should offer: BIS/IEC-compliant installations High-quality materials like copper-bonded rods or GI pipes Soil resistivity testing and system design Installation, maintenance, and testing services ✅ Tip: Always request a test report and check the provider’s certifications before finalizing your vendor. Benefits of Choosing Local Experts in Pune Local earthing experts understand Pune’s geological and environmental conditions. This allows them to design grounding systems that are efficient, safe, and cost-effective. By working with a local company, you also benefit from faster service, site-specific support, and better compliance with municipal standards. Final Thoughts If you’re searching for reliable and certified earthing solutions in Pune, Maharashtra, don’t compromise on quality or safety. From chemical earthing to full-scale industrial solutions, choosing the right provider ensures long-term protection for people and property. 🔗 Contact us today to get a free site assessment in Pune. – https://uprotecgroup.com/contact-us/📄 Read more about our earthing system designs – https://uprotecgroup.com/blog/

HOW TO DESIGN EARTHING

Blog HOW TO DESIGN EARTHING HOW TO DESIGN EARTHING Designing an effective earthing system requires careful consideration of various factors to ensure proper safety and performance. Here are the key steps involved in designing an earthing system: Determine the Purpose and Requirements: Understand the specific purpose of the earthing system, such as equipment safety, lightning protection, or grounding of electrical systems. Identify any relevant standards or regulations that must be followed in the design process. Soil Resistivity Testing: Conduct soil resistivity testing at the installation site. This involves measuring the electrical resistance of the soil at various depths to determine its conductivity. Soil resistivity data helps in selecting the appropriate earthing design and materials. Calculate Required Earth Electrode Resistance: Determine the maximum allowable earth electrode resistance based on the requirements and standards applicable to the installation. The permissible resistance depends on the specific application and the expected fault current. Select Earthing Electrode Type: Based on the soil resistivity, choose the type of earthing electrode to be used. Options include copper or GI rods, plates, or strips. Consider factors such as conductivity, corrosion resistance, and cost-effectiveness. Determine Layout and Configuration: Determine the layout and configuration of the earthing system. Consider the location of the main earthing electrode, the number and spacing of additional electrodes, and the path of the earthing conductors. Design should provide a low-resistance path for fault currents to flow into the ground. Calculate Required Conductor Size: Calculate the required size of earthing conductors based on the maximum expected fault current and the allowable voltage drop. Proper conductor sizing ensures efficient fault current dissipation and minimizes voltage rise. Select Backfill Material: Choose an appropriate backfill material to enhance the conductivity and moisture retention around the earthing electrode. The backfill material should provide good electrical contact with the electrode and maintain its conductivity over time. Consideration for Lightning Protection: If the earthing system is intended for lightning protection, additional considerations may be necessary. This includes incorporating lightning rods, air terminals, and down conductors into the overall design. Documentation and Drawings: Prepare detailed documentation and drawings of the earthing system design, including electrode layouts, conductor sizing, and any relevant calculations. These documents will serve as references during installation, maintenance, and future modifications. Installation and Testing: Ensure proper installation of the earthing system components, including electrodes, conductors, and bonding connections. Conduct testing, such as earth resistance testing, to verify the performance and compliance of the earthing system. Conclusion Remember, designing an earthing system can be complex, and it is essential to consult with a qualified electrical engineer or a professional experienced in earthing system design to ensure compliance with local regulations and industry standards. Their expertise will help ensure the safety and effectiveness of the earthing system for the specific application.

GI VS COPPER EARTHING

Blog GI VS COPPER EARTHING GI VS COPPER EARTHING When it comes to earthing systems, two commonly used materials are copper and galvanized iron (GI). Each material has its own advantages and considerations. Let’s compare GI and copper earthing to understand their differences: Conductivity: Copper is an excellent conductor of electricity and offers higher conductivity compared to GI. This means that copper earthing systems have lower resistance and provide a more efficient path for electrical currents to flow into the ground. As a result, copper earthing can offer better grounding performance, particularly in applications where low resistance is critical, such as in high-voltage installations or sensitive electronic equipment. Corrosion Resistance: Copper is highly resistant to corrosion, making it a durable choice for earthing systems. It does not easily degrade over time, even in corrosive soil conditions. On the other hand, GI is susceptible to corrosion and may require additional protective measures, such as galvanization or regular maintenance, to prevent rusting and ensure long-term performance. Cost: GI is generally less expensive than copper, which makes it a more cost-effective option for earthing systems, especially in large-scale installations or when budget constraints are a consideration. However, it’s important to weigh the cost savings against the long-term benefits and performance offered by copper earthing systems. Maintenance: Copper earthing systems generally require less maintenance compared to GI systems. Copper’s corrosion resistance reduces the need for regular upkeep and replacement. GI earthing systems, on the other hand, may require periodic inspections, cleaning, and re-galvanization to prevent corrosion and maintain performance. Soil Resistivity: The choice of earthing material may also depend on the soil resistivity at the installation site. Copper has lower resistance and can compensate for higher resistivity soil conditions, ensuring effective earthing. GI may be suitable for locations with lower soil resistivity, where its conductivity is sufficient for maintaining a low-resistance path to the ground. Application Specificity: In certain applications, such as telecommunications or lightning protection systems, copper earthing is often preferred due to its superior conductivity and grounding efficiency. GI earthing may be suitable for general electrical earthing purposes in residential or small-scale commercial installations, where cost-effectiveness is a priority. Conclusion In summary, copper earthing offers higher conductivity, better corrosion resistance, and lower maintenance requirements compared to GI earthing. However, GI can be a cost-effective alternative in certain applications. The choice between the two materials should be based on factors such as the specific requirements of the installation, budget considerations, soil conditions, and long-term performance expectations. Consulting with a qualified electrical engineer or a professional experienced in earthing systems can provide valuable guidance in selecting the most appropriate material for a particular application.