HOW TO MEASURE SOIL RESISTIVITY

Blog HOW TO MEASURE SOIL RESISTIVITY HOW TO DO SOIL RESISTIVITY To measure soil resistivity, you can follow these general steps: Equipment and Materials: Soil resistivity meter: This is a specialized instrument used to measure the electrical resistance of the soil. Test electrodes: These are metal probes or stakes that are inserted into the ground for the resistivity measurement. Connecting cables: These cables are used to connect the soil resistivity meter to the test electrodes. Auxiliary equipment: You may need items such as a mallet, tape measure, and marking flags for the testing process. Test Point Selection: Choose a representative test location that is close to the area where the earthing system will be installed. Ensure the test point is clear of any obstructions like rocks, vegetation, or underground utilities. Measure the distance from the test point to nearby structures, utilities, or other significant features that may affect the soil resistivity. Test Setup: Connect the cables from the soil resistivity meter to the test electrodes according to the manufacturer’s instructions. Insert the test electrodes into the ground at the selected test point. The depth and spacing of the electrodes depend on the type of soil and the desired depth of investigation. Common configurations include the Wenner or Schlumberger arrays. Ensure good contact between the electrodes and the soil. Use a mallet to drive the electrodes gently into the ground until they are secure. Measurement Procedure: Follow the specific instructions provided by the soil resistivity meter manufacturer to initiate the measurement process. The instrument will typically send an electrical current through the outer pair of electrodes, while the inner pair of electrodes measures the resulting voltage drop. The meter will calculate and display the soil resistivity value based on the voltage and current measurements. Take multiple measurements at different depths or electrode spacings to obtain a representative average resistivity value. Data Analysis and Interpretation: Record the resistivity values obtained at each measurement point. Analyze the data to determine the average soil resistivity and identify any variations or anomalies in the soil profile. Consider the geological characteristics of the site, such as soil type, moisture content, and presence of rocks or other geological formations, as they can influence the resistivity measurements. Use the obtained soil resistivity values as input for the design of the earthing system, selecting appropriate materials and configurations to meet the required performance criteria. Conclusion It’s important to note that soil resistivity measurements are best performed by professionals or individuals with experience in using soil resistivity meters and interpreting the results. The accuracy and reliability of the measurements can significantly impact the design and performance of the earthing system.

Types of Earthing: Essential Guide for Electrical Safety

Blog Types of Earthing: Essential Guide for Electrical Safety What is Earthing? Earthing, also known as grounding, is a crucial part of electrical and lightning protection systems. It ensures a low-resistance path for electrical currents to flow safely into the ground, preventing electrical hazards and protecting people and equipment. Understanding the different types of earthing systems helps in selecting the most effective method for various applications. Why is Earthing Important? Enhances electrical safety by preventing electric shocks. Protects electrical appliances from voltage surges. Reduces the risk of fire caused by electrical faults. Ensures system stability in industrial and residential installations. Types of Earthing Systems 1. Plate Earthing Plate earthing involves burying a large metal plate, typically made of copper or galvanized iron, vertically in the ground. This plate acts as an electrode, helping dissipate electrical energy efficiently. Applications: Commonly used in residential, commercial, and industrial buildings. 2. Rod Earthing Rod earthing consists of metal rods (copper or galvanized iron) driven deep into the ground. Engineers may install multiple rods to increase conductivity. Applications: Ideal for high-resistivity soil and space-constrained areas like urban locations and rocky terrains. 3. Pipe Earthing Pipe earthing uses galvanized iron or copper pipes buried in the ground to provide a low-resistance path for electrical currents. Applications: Widely used in residential and small commercial buildings due to its efficiency and cost-effectiveness. 4. Strip Earthing Strip earthing involves burying a metal strip (copper or galvanized iron) horizontally in the ground, offering a large contact area with the soil for better dissipation of electrical energy. Applications: Suitable for areas with high soil resistivity or where space constraints limit other earthing types. 5. Ring Earthing Ring earthing consists of a circular metal conductor, such as a copper strip or wire, buried around a structure. This continuous loop provides a reliable path for electrical currents. Applications: Commonly used in power substations and electrical distribution systems. 6. Combination Earthing In some cases, engineers use a combination of different earthing methods to optimize performance. Example: A combination of rod, plate, and strip earthing may be used based on soil conditions and project requirements. Choosing the Right Earthing System The selection of an appropriate earthing system depends on several factors: Soil resistivity – Determines conductivity efficiency. Electrical load – Affects the required earthing capacity. Type of structure – Residential, commercial, or industrial requirements vary. Local regulations – Compliance with electrical safety standards. Conclusion Proper earthing is essential for electrical safety and system reliability. Understanding different earthing methods helps in choosing the best option for a specific application. Consulting with a qualified electrical engineer ensures the most effective earthing solution. By implementing the right earthing system, you can prevent electrical hazards and enhance the safety of your installations.

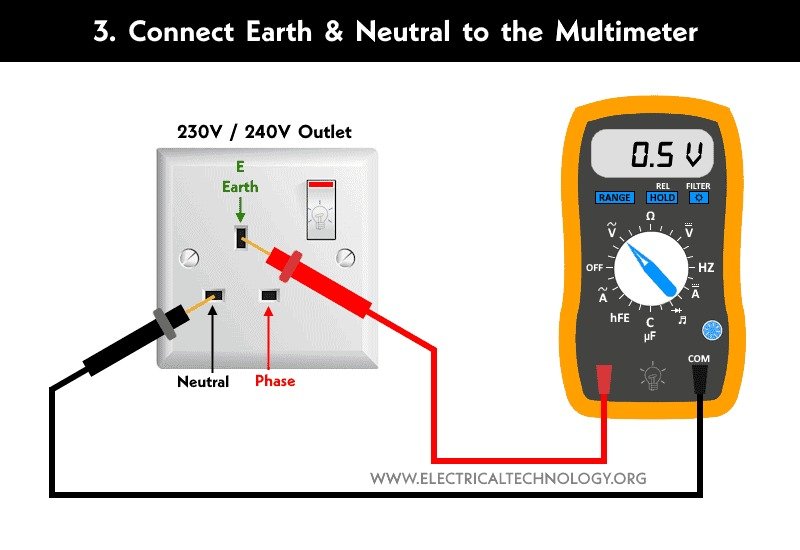

How to Reduce Earth-to-Neutral Voltage: Causes, Fixes & Expert Tips

Blog How to Reduce Earth-to-Neutral Voltage: Causes, Fixes & Expert Tips PROCESS TO REDUCE EARTH TO NEUTRAL VOLTAGE Reducing the voltage difference between earth and neutral is crucial for ensuring the safety and efficiency of electrical systems. An elevated earth-to-neutral voltage, such as 5 volts, can indicate underlying issues that need to be addressed promptly. Below are steps to reduce earth to neutral voltage mitigate this voltage difference: Identify the Cause: Determine the reason behind the elevated Earth to Neutral voltage.Issues such as improper grounding, high-resistance connections, unbalanced loads, or faulty equipment could cause it. Identifying the root cause will help in devising an appropriate solution. Check Grounding System: Ensure that the grounding system is properly installed and connected. Check the integrity of the grounding electrode, such as the earth electrode or grounding rod, to ensure low resistance. Make sure the grounding conductors are correctly sized and securely connected. Verify Neutral Connection: Carefully inspect and secure the neutral conductor connections, particularly at the main distribution panel or transformer. Loose or faulty connections can cause voltage imbalances. Ensure that the neutral conductor is properly sized and securely connected. Balance the Loads: Uneven distribution of loads among phases can lead to voltage imbalances. To maintain balanced voltages, evenly distribute the loads across all phases by redistributing them or using load balancing techniques. Minimize Electrical Noise: High levels of electrical noise or harmonics can cause voltage imbalances. Install appropriate filters or surge protectors to minimize noise and harmonics. This can help in reducing voltage differentials between Earth and Neutral. Address Equipment Issues: Faulty or malfunctioning equipment can cause voltage imbalances. Identify and rectify any faulty equipment that may be contributing to the Earth to Neutral voltage difference. Replace or repair equipment as necessary. Seek Professional Assistance: If the voltage difference persists or you are unsure about the cause or solution, therefore, seek assistance from a qualified electrician or electrical engineer. They can perform a detailed analysis of the system, diagnose the issue accurately, and provide tailored recommendations for reducing the Earth to Neutral voltage difference. Conclusion To mitigate these hazards, implement various protective measures, including installing lightning protection systems, using surge protection devices, applying proper grounding and bonding techniques, and adherence to safety standards and regulations. It is essential to consult with qualified professionals or lightning protection specialists to assess and implement appropriate measures based on the specific requirements of the site or structure.

Chemical Maintenance Earthing: Enhancing Safety and Electrical System Performance

Blog Chemical Maintenance Earthing: Enhance Safety & Performance Chemical Maintenance Earthing: Enhancing Safety and Electrical System Performance In electrical systems, maintaining a reliable and efficient earthing system is crucial for ensuring safety and optimal performance. Chemical maintenance earthing, also known as chemical electrode earthing, is an advanced method that offers enhanced conductivity and longevity compared to conventional earthing systems. In this article, we will explore what chemical maintenance earthing is, how it works, and the benefits it offers in terms of safety and electrical system reliability. Understanding Chemical Maintenance Earthing: Chemical maintenance earthing is a specialized technique that involves the use of conductive compounds to enhance the conductivity of the earth electrode and soil interface. It ensures a low-resistance path for electrical currents to flow into the ground, thereby facilitating effective earthing and grounding of electrical systems. Chemical maintenance earthing involves the following steps: Preparation of Earth Electrode: A high-quality copper or galvanized iron electrode is prepared, ensuring proper dimensions and surface area. The electrode is typically in the form of a rod or plate, depending on the application and soil conditions. Application of Conductive Compound: A conductive compound, often composed of a mixture of conductive salts and other additives, is applied to the surface of the earth electrode. This compound enhances the conductivity of the electrode and forms a conductive layer at the electrode-soil interface. Installation and Backfilling: The prepared earth electrode is installed in the ground according to the recommended depth and configuration. The electrode is surrounded by a backfill material that helps maintain moisture and conductivity around the electrode. Regular Maintenance: Periodic inspections and maintenance are essential for chemical grounding maintenance systems. This may include checking the condition of the electrode, replenishing the conductive compound if necessary, and ensuring proper moisture levels in the surrounding soil. Benefits of Chemical Maintenance Earthing: Improved Conductivity: The use of conductive compounds in chemical maintenance earthing significantly enhances the conductivity of the earth electrode and soil interface. This ensures low-resistance grounding and minimizes the risk of electrical hazards, such as electric shocks and equipment damage. Longevity and Stability: chemical grounding maintenance systems offer long-term stability and durability. The conductive compounds help protect the earth electrode against corrosion and maintain its conductivity over time, resulting in a reliable and long-lasting grounding solution. Resistance to Drying and Moisture Loss: The conductive compounds used in chemical grounding maintenance systems can retain moisture in the soil, even in dry or arid conditions. This helps maintain a consistent conductivity level, ensuring reliable earthing performance throughout different seasons and climates. Maintenance Convenience: chemical grounding maintenance systems require periodic inspections and maintenance, but the frequency is typically lower compared to traditional earthing systems. The conductive compounds provide an added layer of protection, reducing the need for frequent reinstallation or adjustment of the earth electrode. Conclusion Chemical maintenance earthing offers an advanced and efficient solution for achieving reliable and safe grounding in electrical systems. With its improved conductivity, longevity, stability, and resistance to drying, this method provides a valuable alternative to conventional earthing systems. By adopting chemical grounding maintenance techniques, electrical systems can benefit from enhanced safety, reduced electrical hazards, and improved overall performance. Consulting with a qualified electrical engineer or a professional experienced in chemical grounding maintenance is recommended to ensure proper design, installation, and maintenance of such systems.

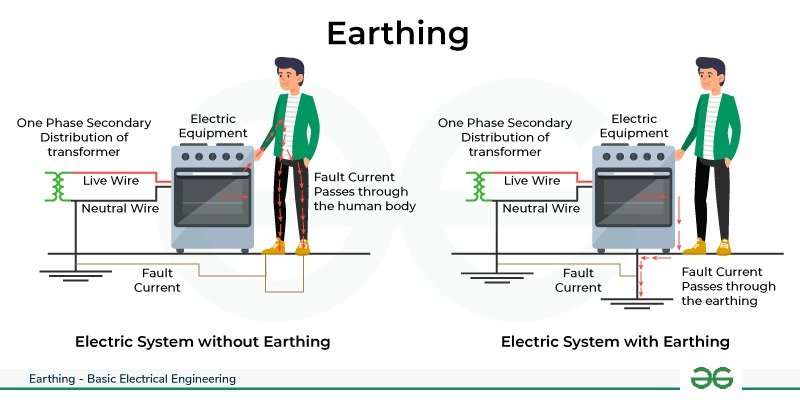

WHY EARTHING IS REQUIRED

Blog WHY EARTHING IS REQUIRED Why Do You Need Earthing? Essential Benefits and Importance Earthing, also known as grounding, plays a crucial role in electrical systems and is required for several reasons. Safety: One of the primary reasons for earthing is to ensure safety. Earthing provides a safe path for electrical faults and abnormal currents to flow into the ground, reducing the risk of electric shock to people and preventing damage to equipment. Grounding the electrical system directs excess current away from people and objects, promoting a safe operating environment. Fault Current Dissipation: As a result, when a fault occurs, such as a short circuit or insulation failure, excessive current can rapidly flow through the electrical system, potentially causing damage. Earthing helps dissipate this fault current safely into the ground, preventing it from causing damage to equipment, overheating conductors, or creating electrical hazards. Voltage Stabilization: Earthing helps stabilize voltage levels within an electrical system. By providing a low-resistance path to the ground, earthing reduces the risk of voltage fluctuations, transient surges, and harmonics. This ensures that equipment and appliances receive a stable and consistent voltage supply, promoting their proper functioning and longevity. Lightning Protection: Earthing is essential for protecting structures and equipment from the damaging effects of lightning strikes. Lightning carries immense amounts of electrical energy, and without a proper grounding system, it can cause fires, explosions, and severe damage. Earthing provides a path for lightning currents to safely dissipate into the ground, reducing the risk of damage to structures and electrical systems. Equipment Protection: Proper earthing helps protect sensitive electrical equipment from damage caused by voltage surges, electromagnetic interference, and transient events. By providing a low-impedance path for fault currents and transient events, earthing diverts these currents away from equipment, reducing the risk of damage and extending the lifespan of electrical devices. Compliance with Regulations: Electrical codes and regulations often mandate the installation of proper earthing systems to ensure safety and prevent electrical hazards. Compliance with these regulations is essential to meet legal requirements, obtain permits, and maintain insurance coverage. Conclusion Ultimately, earthing enhances safety, dissipates fault currents, stabilizes voltages, protects against lightning strikes, safeguards equipment, and ensures compliance with electrical regulations. Properly designed and installed earthing systems are essential for the reliable and safe operation of electrical systems in various applications, ranging from residential buildings to industrial facilities.

Conventional Copper Lightning Arrestor: Protection Against Lightning Strikes

Blog Conventional Copper Lightning Arrestor: Protection Against Lightning Strikes Conventional Copper Lightning Arrestor: Protection Against Lightning Strikes When it comes to protecting lives and property from the destructive force of lightning strikes, conventional copper lightning arrestors have consistently proven to be a reliable and time-tested solution. Moreover, their durability and effectiveness make them a preferred choice for ensuring safety in various applications. For decades, these devices have been effectively deployed in various structures to mitigate the risks associated with lightning-related incidents. In this article, we will explore what a conventional copper lightning arrestor is, how it works, and the benefits it offers in safeguarding against the devastating impact of lightning strikes. Understanding Conventional Copper Lightning Arrestor: A conventional copper lightning arrestor, also known as a lightning rod or air terminal, is a simple yet effective device designed to protect structures from lightning strikes. It comprises a metal rod, typically made of copper or aluminum, mounted at the highest point of a structure. The rod acts as a target for lightning strikes, providing a path of least resistance for the electrical discharge to follow. How Does it Work? A conventional copper lightning arrestor creates a preferential pathway for lightning to strike and diverts the electrical current away from the structure it protects. When lightning approaches, the highly conductive metal rod acts as an attractive point for the electrical discharge. As lightning strikes the rod, it follows the path of least resistance provided by a network of down conductors and grounding systems. The down conductors, made of copper or aluminum, are installed vertically along the sides of the structure, ensuring a direct path from the lightning rod to the grounding system. The grounding system, consisting of buried conductors and grounding electrodes, safely disperses the electrical energy into the ground, minimizing the risk of damage to the structure and its occupants. Benefits of Conventional Copper Lightning Arrestor: Simplicity and Reliability: Conventional copper lightning arrestors offer a straightforward and reliable approach to lightning protection. Their design is based on well-established principles, and they have been used successfully for many years. This simplicity contributes to their proven effectiveness and durability. Cost-Effectiveness: Compared to some advanced lightning protection technologies, conventional copper lightning arrestors are generally more cost-effective to install and maintain. Their straightforward design and availability of materials make them accessible to a wide range of structures, from residential buildings to industrial facilities. Compatibility with Existing Structures: One of the notable advantages of conventional copper lightning arrestors is their compatibility with existing structures. You can retrofit these devices onto buildings without significant modifications, making them an attractive option for updating lightning protection on structures. Well-Established Standards: The installation and design of conventional copper lightning arrestors adhere to internationally recognized standards and guidelines for lightning protection systems. These standards ensure that the devices are installed correctly, providing reliable protection and meeting safety requirements. Conclusion Conventional copper lightning arrestors remain a trusted and effective solution for protecting lives and property from lightning strikes. Their simplicity, reliability, cost-effectiveness, and compatibility with existing structures make them a practical choice for various applications. Using these proven devices helps reduce the risks of lightning damage and improves the safety of communities and infrastructure.

WHEN EARTHING IS REQUIRED

Blog WHEN EARTHING IS REQUIRED WHEN EARTHING IS REQUIRED Earthing, or grounding, should be implemented in various scenarios to ensure safety and proper functioning of electrical systems. Here are some common instances when earthing is required: Electrical Installations: Earthing is essential in electrical installations of residential, commercial, and industrial buildings. It includes grounding the electrical distribution system, panels, and equipment. This helps prevent electric shock hazards, dissipate fault currents, and stabilize voltage levels. Power Substations and Transformers: Earthing is crucial in power substations and transformer installations. It ensures the safe dissipation of fault currents and protects equipment from damage caused by electrical faults or lightning strikes. Equipment and Machinery: Electrical equipment, machinery, and appliances should be properly grounded to protect operators and users from electric shocks. This is particularly important for equipment with exposed metal parts or conductive surfaces. Lightning Protection Systems: Effective earthing is an integral part of lightning protection systems. Grounding conductors and grounding electrodes are installed to provide a low-resistance path for lightning currents to safely dissipate into the ground, thereby protecting structures and equipment. Telecommunication Systems: Telecommunication systems, such as telephone networks and data centers, require proper grounding to protect against power surges, electromagnetic interference, and static electricity. Grounding ensures proper signal integrity and protects sensitive electronic equipment. Hazardous Environments: In hazardous environments where flammable or explosive substances are present, proper earthing is crucial. It helps prevent the build-up of static electricity, which could cause sparks and ignite flammable materials. Electronic Equipment and Circuits: Many electronic devices and circuits require proper grounding to minimize noise, interference, and voltage fluctuations. Grounding helps maintain signal integrity, reduce electromagnetic interference, and ensure reliable operation. Outdoor Structures: Outdoor structures, such as streetlights, traffic signals, and communication towers, should be properly grounded to protect against lightning strikes and provide a safe path for fault currents. Conclusion It is important to note that specific grounding requirements may vary depending on local electrical codes, regulations, and industry standards. It is recommended to consult with a qualified electrician, electrical engineer, or relevant regulatory authorities to ensure compliance with the appropriate grounding guidelines for your specific application.

The Importance of Lightning Arrestors for Industries, Residential, and Commercial Sites

Blog THE IMPORTANCE OF LIGHTNING ARRESTORS FOR INDUSTRIES, RESIDENTIAL AND COMMERCIALS SITE IMPORTANCE OF LIGHTNING ARRESTORS IN INDUSTRIES AND RESIDENTIAL COMMERCIALS SITE Lightning arrestors, also known as lightning surge protectors or lightning rods, play a crucial role in protecting industries, residential areas, and commercial sites from the damaging effects of lightning strikes. Here’s why the importance of lightning arrestor is critical in these settings: Protection of People and Property: Lightning strikes pose a significant risk to the safety of individuals and the integrity of structures. By installing lightning arrestors, the electrical energy from a lightning strike is safely redirected to the ground, reducing the risk of injury or loss of life due to electric shock. It also helps prevent structural damage, fires, and explosions that can result from lightning strikes. Protection of Electrical Systems: Lightning carries immense electrical energy, and a direct or nearby strike can cause power surges and transient voltages that can damage electrical equipment and systems. Lightning arrestors provide a path of least resistance for the lightning current to follow, diverting it away from sensitive equipment and minimizing the risk of damage. This helps protect electrical systems, appliances, and devices from costly repairs or replacements. Protection against Voltage Spikes and Transients: Even if a direct lightning strike does not occur, the electromagnetic field generated by nearby strikes can induce voltage spikes and transients in electrical systems. These voltage disturbances can lead to equipment malfunction, data loss, and disruptions in operations. Lightning arrestors help dissipate these transient voltages, safeguarding electronic equipment and maintaining the integrity of critical systems. Compliance with Safety Standards: Industries, residential areas, and commercial sites are subject to safety regulations and standards that require adequate lightning protection measures. Installing lightning arrestors ensures compliance with these standards and provides the necessary safety measures to protect people and property. Preservation of Data and Information: Lightning-induced power surges and transients can damage data centers, computer networks, and communication systems, resulting in data loss or corruption. Lightning arrestors help prevent such damage by diverting lightning currents away from sensitive equipment and preserving valuable data and information. Insurance Requirements: Many insurance policies, particularly for industries and commercial sites, require the installation of lightning protection systems, including lightning arrestors. Compliance with these requirements is necessary to maintain insurance coverage and mitigate potential financial losses in the event of lightning-related damage. Peace of Mind: Lightning arrestors provide peace of mind to occupants, business owners, and facility managers. Knowing that appropriate lightning protection measures are in place helps alleviate concerns about the safety of people, the protection of assets, and the continuity of operations. Conclusion It is important to note that the design, installation, and maintenance of lightning protection systems, including lightning arrestors, should be carried out by qualified professionals with expertise in lightning protection and in accordance with relevant standards and guidelines. Their knowledge and experience ensure the effectiveness and reliability of the lightning protection measures implemented.

Early Streamer Lightning Arrestor: Protecting Lives and Property from Lightning Strikes

Blog Early Streamer Lightning Arrestor: Protecting Lives and Property from Lightning Strikes Lightning strikes are a natural phenomenon that can be both awe-inspiring and dangerous. While their beauty can captivate us, the destructive power of lightning is undeniable. Each year, lightning causes significant damage to property and claims numerous lives worldwide. To mitigate the risks associated with lightning strikes, innovative technologies have been developed, and one such advancement is the Early Streamer Lightning Arrestor (ESLA). In this article, we will explore what an Early Streamer Lightning Arrestor is, how it works, and the benefits it offers in safeguarding lives and property. Understanding Early Streamer Lightning Arrestor (ESLA): An Early Streamer Lightning Arrestor is an advanced lightning protection device designed to intercept and divert lightning strikes before they can reach vulnerable structures. It operates on the principle of creating a preferred path for the lightning to follow, diverting it away from the protected area. How Does it Work? ESLAs work by generating a streamer ahead of the main lightning strike. They contain a set of ionizing electrodes that emit upward upward streamers into the atmosphere when a thunderstorm approaches. These upward streamers extend towards the descending stepped leader from the cloud. The purpose of the streamers is to initiate a connection with the descending lightning channel, effectively creating a conductive path for the lightning discharge to follow. The Early Streamer Lightning Arrestor uses an advanced triggering system that ensures the timely initiation of the upward streamers. By initiating the streamers early, the device extends the zone of protection and increases the likelihood of intercepting the lightning strike, diverting it safely to the ground. This early interception and diversion mechanism significantly reduces the risk of damage caused by lightning strikes. Benefits of Early Streamer Lightning Arrestor Enhanced Protection Range: One of the primary advantages of an Early Streamer Lightning Arrestor is its ability to cover a larger area compared to conventional lightning protection systems. The early initiation of the upward streamers ensures a larger protective radius, safeguarding a greater zone against potential lightning strikes. Improved Safety: By intercepting and diverting lightning strikes before they reach the protected area, ESLAs reduce the risk of injury or loss of life due to lightning-related incidents. They provide peace of mind to individuals and organizations by offering a proactive defense against a potentially devastating natural phenomenon. Property Protection: Lightning strikes can cause extensive damage to structures, including fires, electrical system failures, and structural damage. Early Streamer Lightning Arrestors minimize the impact of lightning strikes by channeling the electrical discharge safely to the ground, preventing damage to buildings, equipment, and valuable assets. Compliance with Standards: ESLAs are designed and manufactured in compliance with international standards and guidelines for lightning protection systems. Their efficacy has been extensively tested and verified, providing a reliable solution that meets the highest safety standards. Conclusion As the risk of lightning strikes continues to pose a threat to lives and property, it is crucial to employ effective lightning protection measures. Early Streamer Lightning Arrestors offer a robust solution by intercepting and diverting lightning strikes before they reach vulnerable areas. With their enhanced protection range and improved safety features, ESLAs are a crucial part of modern lightning protection systems. These devices comply with industry standards, ensuring reliable defense against lightning strikes. Investing in such advanced technologies helps reduce risks and safeguards communities and infrastructure from devastating effects.

HOW CAN WE IMPROVE EARTHING RESISTANCE

Blog HOW CAN WE IMPROVE EARTHING RESISTANCE HOW CAN WE IMPROVE EARTHING RESISTANCE When faced with high earth resistance, there are several solutions and measures that can be taken to improve earthing resistance and enhance the grounding system. Implementing these techniques ensures better electrical safety and system reliability. Here are some potential solutions: Increase the Number of Grounding Electrodes: Adding more grounding electrodes can help reduce the overall resistance of the grounding system. This can be done by installing additional ground rods, ground plates, or grounding grids. Increasing the number of electrodes provides more contact points with the earth, allowing for better dissipation of fault currents and lowering the resistance. Improve Grounding Electrode Quality: Ensure that the grounding electrodes, such as ground rods or plates, are in good condition and made of high-quality materials. Corroded or deteriorated electrodes may have higher resistance and can be replaced with new ones. It is also essential to ensure proper installation techniques, such as ensuring good contact between the electrode and the surrounding soil. Enhance Soil Moisture Content: Dry or resistive soil can contribute to higher earth resistance. Measures to improve soil moisture can include watering the area around the grounding electrodes or installing soil moisture enhancement systems. Moisture in the soil helps improve conductivity and reduce resistance. Chemical Enhancement of Soil: Use soil enhancement compounds to improve soil conductivity. Mix these compounds, such as ground enhancement materials or conductive backfills, with the soil surrounding the grounding electrodes. They enhance the conductivity of the soil, reducing resistance and improving grounding effectiveness. Improve Grounding System Design: Evaluate the overall grounding system design to ensure it is optimized for reducing earth resistance. Factors to consider include the placement and layout of grounding electrodes, the type and size of conductors used, and the connection points between components. Working with an experienced electrical engineer or grounding specialist can help ensure an effective and efficient grounding system design. Perform Soil Resistivity Testing: Conduct a soil resistivity test to accurately determine the resistivity of the soil at the grounding location. This information can help in selecting the appropriate grounding system design and determining the necessary measures to reduce earth resistance effectively. Perform Soil Resistivity Testing: Conduct a soil resistivity test to accurately determine the resistivity of the soil at the grounding location. Ground enhancement materials, such as chemical rods or conductive backfills, specifically reduce resistance and enhance grounding performance. Conclusion It is important to note that addressing high earth resistance requires a systematic and comprehensive approach.A qualified electrical engineer, grounding specialist, or professional electrician should assess the specific conditions, conduct necessary tests, and determine the most appropriate solutions for your grounding system. They can provide expert guidance and ensure compliance with relevant codes and standards.