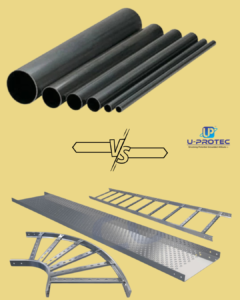

Cable Trays vs Conduits: Which One Should You Choose and Why?

Electrical installations, whether for industrial, commercial, or infrastructure projects, require reliable methods for routing and protecting cables. Two of the most common options are cable trays and conduits. But how do you decide which one is right for your project? In this post, we’ll explore the key differences between cable trays vs conduits, highlight their pros and cons, and guide you toward the best choice based on your application.

What Are Cable Trays?

Cable trays are structural systems used to support and manage cables. They provide an open and flexible route for running multiple cables throughout a facility.

Types of Cable Trays:

- Ladder trays

- Perforated trays

- Solid-bottom trays

- Wire mesh trays

Key Features:

- Easy to install and modify

- Open design allows for heat dissipation

- Ideal for large volumes of low- and medium-voltage cables

What Are Conduits?

Conduits are enclosed pipes, either metallic or non-metallic, that protect individual or grouped cables. They offer a higher level of mechanical and environmental protection.

Types of Conduits:

- Rigid Metal Conduit (RMC)

- Electrical Metallic Tubing (EMT)

- PVC Conduit

- Flexible Metallic Conduit (FMC)

Key Features:

- Enclosed protection

- Suitable for hazardous and wet locations

- Often required by code for specific applications

Cable Trays vs Conduits: A Side-by-Side Comparison

| Feature | Cable Trays | Conduits |

| Installation Speed | Fast and simple | Slower and more labor-intensive |

| Cable Accessibility | Easy to inspect and replace | Difficult once installed |

| Cost Efficiency | More cost-effective for large projects | Higher material and labor cost |

| Flexibility | Easy to add or reroute cables | Requires major work to make changes |

| Protection Level | Moderate physical protection | High mechanical/environmental protection |

| Aesthetic/Space Needs | Open and visible setup | Concealed and neater appearance |

| Best For | Commercial buildings, data centers | Hazardous areas, underground/wet locations |

When to Use Cable Trays

Choose cable trays when:

- You’re managing a large number of cables

- Heat dissipation is important

- You need flexibility for future expansion

- Accessibility for maintenance is a priority

Common applications:

Data centers, industrial automation, commercial buildings

When to Use Conduits

Use conduits when:

- Environmental protection is critical (e.g., wet, corrosive, or hazardous areas)

- Your project needs code-compliant enclosed wiring

- You’re routing power cables that need high mechanical protection

Common applications:

Underground installations, chemical plants, outdoor wiring

Cost Comparison: Cable Trays vs Conduits

While exact pricing varies, cable trays generally require less labor and fewer materials, making them more cost-effective for large-scale installations. Conduits, on the other hand, offer better protection but at a higher cost and installation time.

Compliance and Standards

When choosing between cable trays and conduits, always consider local and international codes:

- NEC (National Electrical Code)

- IEC 61537 (for cable trays)

- IEC 61386 (for conduits)

Some jurisdictions may mandate conduits for specific types of circuits or environments.

Final Verdict: Cable Trays vs Conduits

Both systems have their place. Here’s a quick takeaway:

- Choose cable trays for large-scale, accessible, and cost-effective projects.

- Choose conduits for high-risk, code-sensitive, or environmentally challenging environments.

Still unsure? Always consult a licensed electrical engineer or review your local code requirements.

FAQs

Q1: Can I use both cable trays and conduits in the same project?

A: Yes, many installations use a hybrid approach—trays in accessible areas, conduits in protected or sensitive zones.

Q2: Are cable trays allowed in fire-rated areas?

A: They can be, but you must use fire-rated cable trays and cables, and comply with firestop regulations.

Q3: Which system is easier to maintain?

A: Cable trays are generally easier due to open access to the cables.